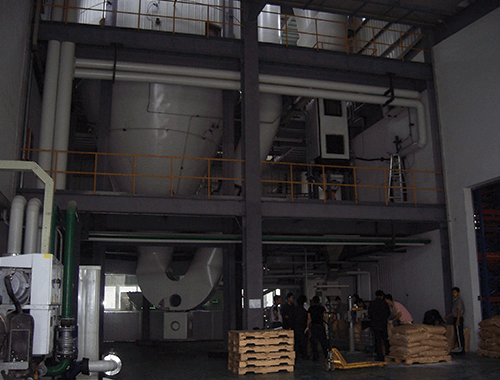

TTPL is a leading Spray Cooler manufacturer in India having more than 10 satisfied oversees customers. TTPL offers the most versatile design of Spray Cooler having several innovative features.

Working Principle

- The process of transforming molten liquid material in to the spherical solid particles using cold air is called as Spray cooling.

- Molten liquid is sprayed in to the stream of uniformly distributed cold air. The molten mass solidifies to produce granules of desired specifications.

- The granules are separated in high efficiency cyclone. The air free from granules is recirculated.

- The spray cooled granules are further cooled in specially designed Bulk Flow Cooler to avoid lump formation during transportation.

Superior Features

- Particle size in wide range (250 to 1000 microns) can be produced in the Spray Cooler

- Most energy efficient system.

- Uniform powder particle size

- High efficiency cyclone separator for powder collection

- Almost nil powder sticking inside the tubes.

- No nozzle chocking.

- Specially designed Bulk Flow Cooler for Post cooling

- Single point powder collection.

- No nozzle dripping during starting and stopping of plant.

- Highest level of instrumentation and the control loops are provided for maintaining consistent powder quality.

- Instrumentation for recording and logging of various vital parameters such as pressure, temperature and flow rate is provided.

- Fully automatic plant with PLC and SCADA based control system

Applications of Spray Cooler

- Palm Stearine

- Encapsulated materials

- Poly ethylene Glycols

- Fats

- Hydrates

- Glycerides

- Stearic acid/ Stearates

- Organic / Inorganic materials

- Waxes