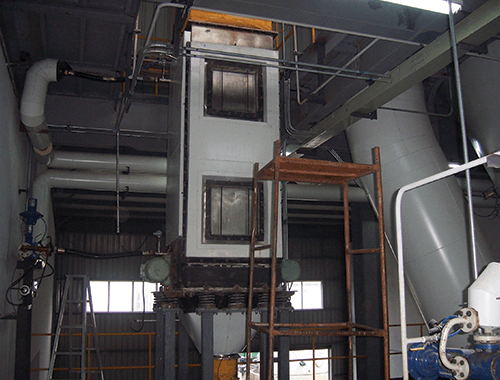

TTPL offers efficient design of bulk flow cooler (BFC) to impart desired quality of finished powder products. In process industries cooling of bulk material is the common requirement. The product to be cooled is typically produced in bulk quantities and requires cooling equipment which must be capable of processing huge quantities of material in an efficient and continuous manner.

Principle of Working

- Spray cooled powder gets collected in the bulk flow cooler from the cyclone.

- In BFC there are number of tubes with chilled brine inside the tube.

- Large surface area comes in contact with powder that can be earthed to remove the static electricity.

- Cooling and static electricity removal is done simultaneously.

Features

- Earthing arrangement to removal of static charges from bulk flow cooler

- Vibrator is provided which avoids bridging of the powder in bulk flow cooler.

- Well instrumented plant with full process automation

Applications

- Food processing industry

- Palm Stearine

- Encapsulated materials

- Poly ethylene Glycols

- Fats

- Hydrates

- Glycerides

- Stearic acid/ Stearates

- Organic / Inorganic materials

- Waxes