Industrial processes using high sulfur fuels such as Coal, Pet Coke, heavy oil etc emit sulfur dioxide gas in large quantities. These emissions are harmful to environment causing acid rain, damage to equipments & public health and shall be subject to stringent statutory norms in near future.

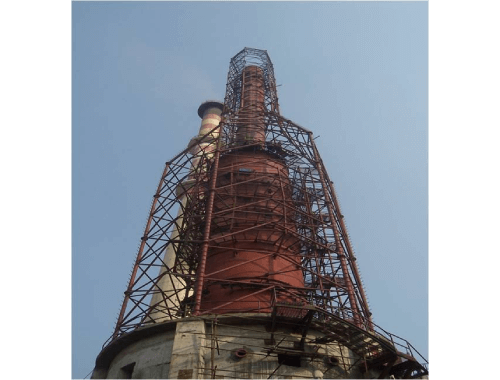

TTPL has established itself as the first FGD manufacturer in India by successfully commissioning first of its kind FGD plant in India on 100 % pet coke fueled captive power plant in North India. This FGD plant is based on wet limestone process which generates Gypsum as a byproduct. This Gypsum is 100% consumed in cement making. The above referred FGD plant in India is operational since February 2012.

TTPL is the only FGD manufacturer in India having 100 % in house design capabilities. TTPL builds Flue Gas Desulphurization (FGD) Plants / DeSOx from first principles along with our in house expertise and design capabilities.

Processes of Flue Gas Desulphurization

TTPL offers Flue Gas Desulphurization (FGD) plants based on following technologies:

Wet Flue Gas Desulphurization System

- Limestone Process

- Sodium Process

- Ammonia Process

- Seawater Process

Semi-Dry Flue Gas Desulphurization System

- Flash Absorption Process (FAP) – Lime based

- Spray drying Process –Lime based

Selection of FGD Process

The selection of FGD process for a given application is dependent on the following factors :-

- The cost and availability of reagents

- Utilization and disposal of by-products

- SO2 content in exhaust gases

- Emission requirements

- Size of the plant

Years of experience in delivering pioneering solutions coupled with robust engineering methodologies and professional project management make TTPL the most dependable FGD manufacturer in India

Applications

Power Plants

- Thermal power plants

- Captive power plants

- Utility Power Plant

- Utility Boilers and Heaters

Smelting Plants

- High sulfur containing Iron Ore smelting

- Copper smelting

- Zinc smelting

- Lead smelting

Incineration Plants

- Hazardous waste incinerator

- Municipal solid waste incinerator

Other plants using high sulfur containing fuel

- Coke ovens.

- Cupola Furnace.

- Carbon black manufacturing.

- Furnace oil / heavy oil fired boiler & Heaters.